Vermatic manufactures and supplies single clamps in many sizes for pipes, tubes, and hoses between 0.250″ and 2.625″. Depending on your needs, we offer single, double, and stacked assemblies. They’re easy to install and lightweight, with plenty of design options available to meet your unique requirements. Learn more about our single clamps, including their benefits and applications.

Single Beta Clamps Explained

Many applications use single clamps for holding and protecting single tubes, hoses, or pipes. Single-hose clamps help reduce the vibration and shock caused by fluid surges in both stationary and mobile industrial applications. You can use single clamps in either one- or two-line double applications.

Types of Single Beta Clamps

Choose from four main types of single clamps for your application, including:

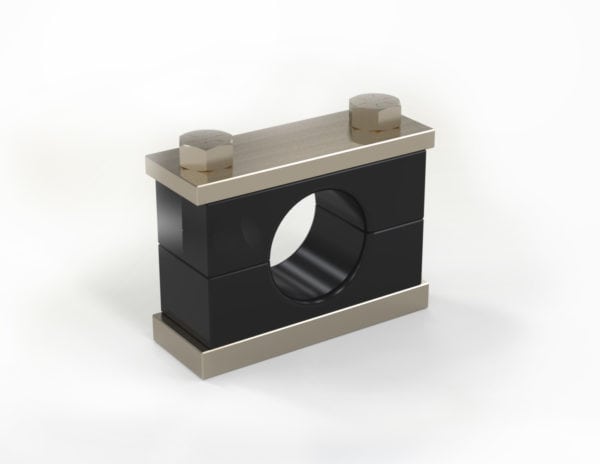

- Weld Mount — One mounting option available for single clamps involves welding the clamp to a base material. It works by welding a base plate to a designated installation point. Vermatic offers a thicker weld base than others, allowing for a stronger weld to be applied. Our weld design also has threaded buttons versus pressed in buttons. The threaded design offers increased strength and eliminates stripping of the bolt when over-torqued.

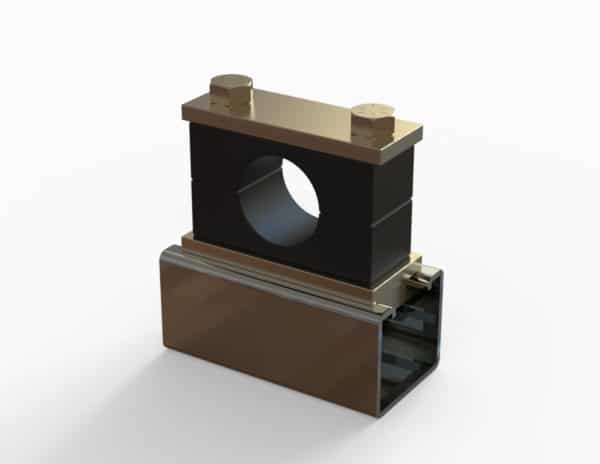

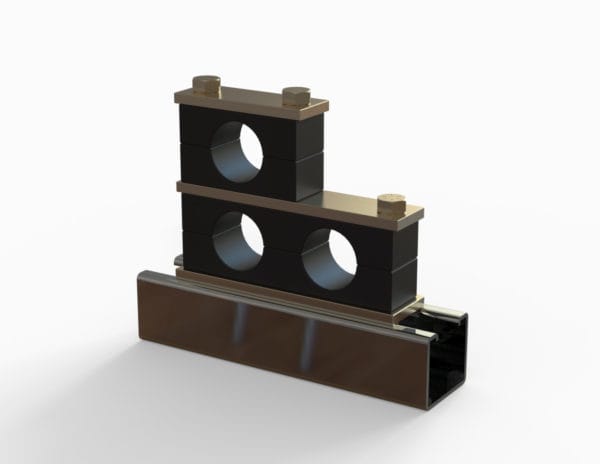

- Channel Mount — Another option for mounting is a channel or rail mount, which allows you to attach the single clamp to an existing rail. . Using this mounting solution, you can move the clamp along the support structure to change its location as needed.

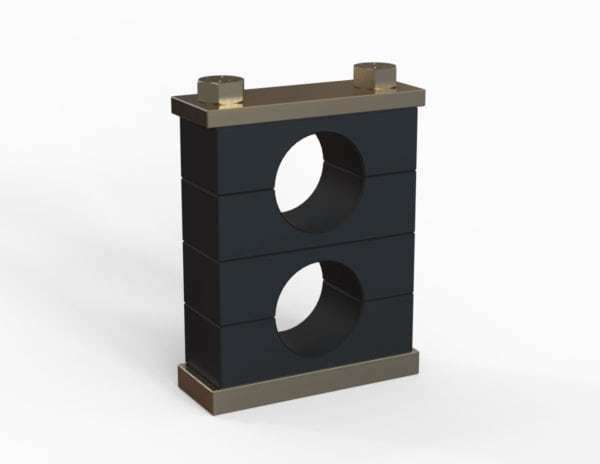

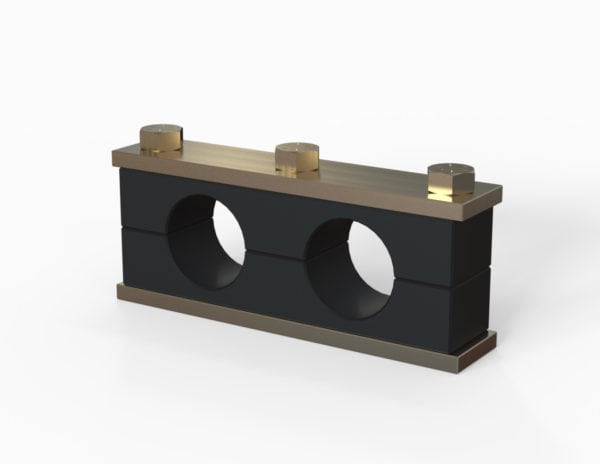

- Single and Double Cushions — Single cushions support a single pipe, hose, or tube at a time, while double cushions support two at a time. Our polypropylene cushions are particularly reliable because of their ability to hold up in harsh conditions.

- Stacked — If you need multiple clamps at different heights, stacked mounts are available. Stack multiple tube clamps on top of each other, or include additional clamps side by side.

Key Features and Benefits

Vermatic’s Single Clamps Are Easy To Install, Lightweight, And Made In The USA. Specific Features Include:

- Stackability

- One- and two-line applications

- A variety of sizes to accommodate hoses, pipes, or tubes from 0.250″ to 2.625″

- Tolerates extreme environments up to 220 °F

- Polypropylene cushion material that withstands harsh conditions, including corrosive liquids

- Aluminum, steel, or stainless steel hardware options

- Base plates that thread the button into the weld base plate instead of just pressing it in (increased durability and elimination of stripping when over-torqued)

- A thicker bottom plate than competing products, creating a larger welding surface

- Weld and channel mount installation options

- Fully assembled or kitted options available for delivery

Applications of Single Beta Clamps

A Large Number Of Applications Across A Wide Range Of Industries Rely On Single Pipe Clamps:

- Agricultural Equipment

- Forklifts

- Cranes

- Backhoes

- Vent and Flare Stacks

- Refuse Haulers

- Sheers, Crushers, and Balers

- Oil and Gas Equipment

- Material Handling Equipment

- Skid Steer Loaders

- Off-highway Equipment

- Hydraulic Power Units

- Tractor Mowers

- Trenchers

- Tree Harvesting Machinery

- Railroad Maintenance Equipment

Single Clamps from Vermatic Inc.

The Vermatic 100 Series single clamps are among the most reliable clamp products available. Use them to secure and protect your hoses, pipes, and tubes with durable support materials and robust mounting options.

In addition to single clamps, Vermatic Inc. designs and manufactures many standard and multi-line clamps, twin clamps, and loose-hanging clamps. We understand that not every off-the-shelf solution works, which is why we also work to provide our customers with the ideal custom designs.

Contact us today to speak with one of our experts. You may also request a quote to begin your order.