Custom Clamps Overview

Vermatic offers a wide selection of high-performance pipe, tube, and hose clamps for original equipment manufacturers (OEMs). Our hydraulic clamp assemblies help to reduce shock and vibration while significantly improving the service life and performance of equipment. We offer a broad range of styles and sizes to meet the demands of stationary and mobile industrial applications.

At Vermatic, we have a team of clamp design experts who have the expertise to bring a customer’s vision to life within budget and on time. From agriculture and oil and gas to material handling equipment, our team has the cross-industry resources and knowledge to meet the demands of even the most complex configurations.

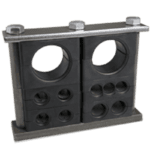

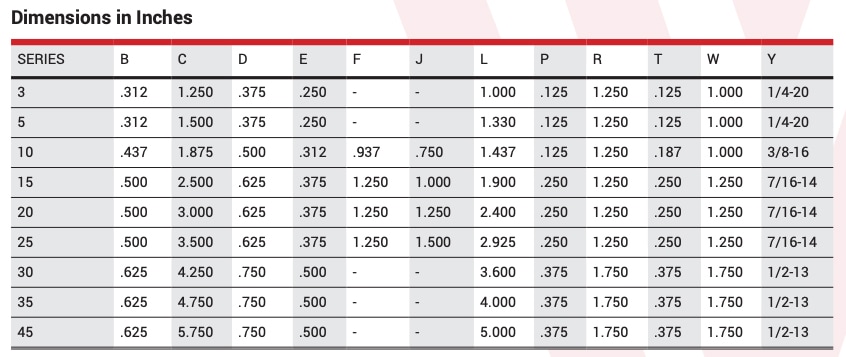

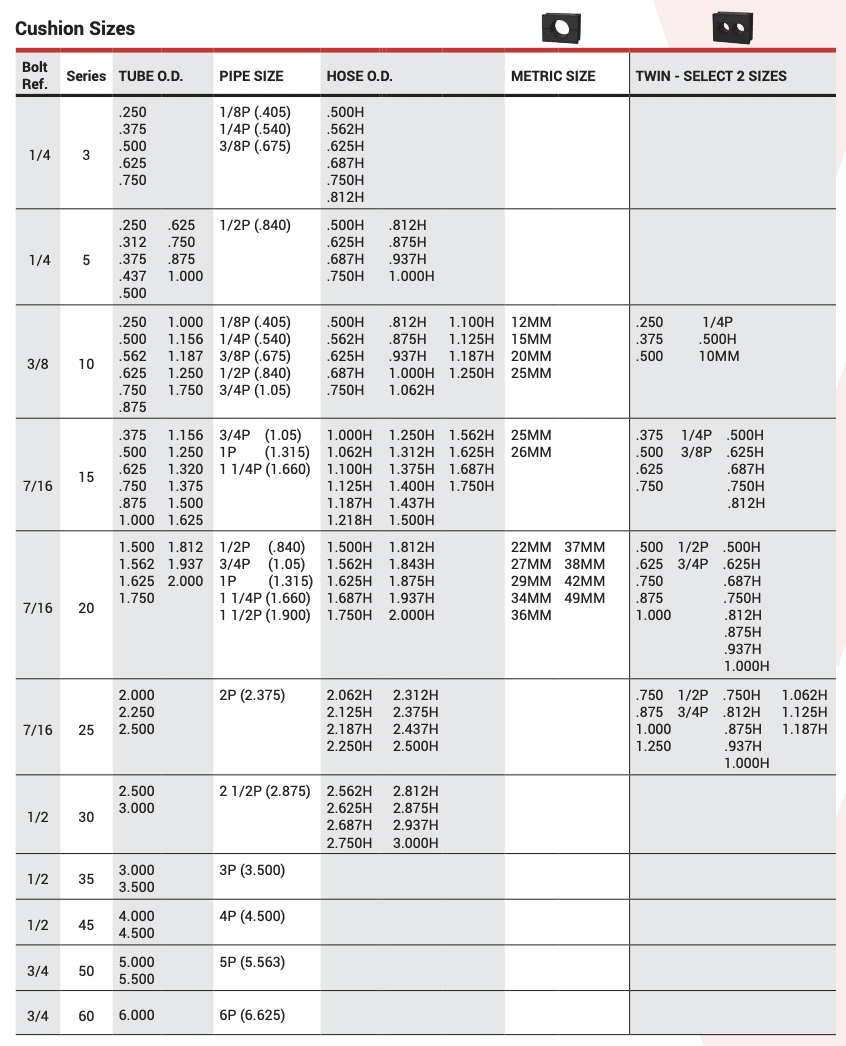

If needed, we have the capabilities to assist our customers with designing exceptional custom clamps, providing flexible options to ensure the clamp design fits the specific demands of the application. Vermatic offers several series designs in single, double, and stacked assemblies for every size and application. Our clamps can accommodate tubes, hoses, and pipes ranging from .250” to 4.000” and are available in channel mount and weld options. All sizes are in stock and made in the USA.

Our custom clamps allow customers to think outside the box with proprietary configurations and custom sizing, unique materials, and multiple lines. We offer in-house machining and molding capabilities, providing customers with a quick turnaround. There are no quantity minimums, and we can ship samples of our products on the same day.

Custom Clamp Process

At Vermatic, we take a design-first approach to provide our clients with a superior level of personalized customer service, which involves the following steps:

Initiate the Process

Contact us to initiate the process. Our design experts will meet with you to discuss specifications, timelines, and unique application requirements. This includes considerations like multiple lines, size configurations, tight spaces, and special materials.

Develop Design

Next, we’ll develop designs for your review and approval, ensuring a perfect fit for the clamp.

Prepare Samples

Then, we quickly prepare samples for your review and approval, with the option for expedited shipping. All clamp products are designed and manufactured in the USA from our Wisconsin production facility. In-house molding and machining capabilities allow for a remarkably fast turnaround.

Fulfillment

Once samples are approved, our production team fulfills and ships your order within your desired timeframe. Custom-size orders with no quantity minimums ensure you receive exactly what you need.

Materials Offered

Customers have access to a range of materials when working with Vermatic. Standard hardware is comprised of steel with the following finishes available:

- Clear Zinc

- Black Oxide

The following special hardware materials are also available:

- Aluminum

- All Grades of Stainless Steel

The cushion always consists of polypropylene material. However, the following materials can be supplied for the cushion insert:

- Nylon

- Plastic

- Rubber

- Aluminum

- All grades of Stainless Steel

Custom Clamps Features & Benefits

For over four decades, Vermatic has been at the forefront of collaborating with OEMs worldwide, emphasizing a design-first approach in crafting custom clamps that cater to a myriad of application requirements. This method brings forth a host of advantages, including:

- Precision in Mounting Options

Through our design-first approach, we provide uniquely tailored mounting solutions. This encompasses versatile options such as weld and channel mount installations, meticulously crafted to align with the specific design requisites of each project. This ensures a seamless integration and optimal performance within the intended application.

- Enhanced Functionality

By prioritizing design from the outset, we have the flexibility to engineer clamps with features that go beyond standard off-the-shelf products. This allows us to fine-tune functionality to match the exacting demands of the project, resulting in a clamp that performs with unparalleled precision and efficiency.

- Customization for Unique Challenges

When confronted with projects that fall outside the scope of readily available products, our design-first approach enables us to tackle unique challenges head-on, tailoring the clamp’s specifications to meet the specific demands of the application. This adaptability ensures that our clamps are a perfect fit, even in the most specialized and complex scenarios.

Customization Options for Stock Clamps

Every Vermatic clamp is available in a range of sizes and styles. Our high-quality clamp assemblies serve diverse mobile and stationary industrial applications across industries. From standard to custom clamps, multiple lines, unique size configurations or special materials – there is no engineering challenge that we can’t handle. Vermatic clamps can be manufactured to different specifications, making it customizable to the following options:

Standard Clamps Customization

Industries Served: Custom Clamp Applications

Vermatic has provided OEMs in the stationary machine and equipment industries with custom clamps to solve the toughest engineering challenges. Over the past several decades, we have partnered closely with distributors representing fluid power, accessories, hose, hydraulic, automatic, and pneumatic markets.

Our immense experience has allowed us to deliver a broad spectrum of capabilities to a wide range of industries that use Vermatic custom clamps for the following applications:

Partner with Vermatic

For over 40 years, our woman-owned company has manufactured fully custom products, delivering high-quality standard and custom clamps for a wide variety of industries and applications.

Contact us to learn more about Vermatic and how our industry-leading products can meet the demands of your specific application. Our vast experience in clamp design allows us to deliver quick turnaround and competitive pricing, making us the number one resource for exceptional service and quality products.